Finally got enough done so that it almost looks like a backhoe. Still got a heck of a long way to go though!

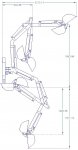

Attached is a spec sheet, in mm ofcourse. Dig depth at 5'11", loading height 6'2".

I'm fairly sure the hoe is way too big for the machine. Nice excuse to get a bigger tractor

Also got a picture of some of the parts done so far. Alot of the parts for the swing joint are done too, and the stabilisers, just not welded together. Waiting for the hydraulics to turn up really....

Attached is a spec sheet, in mm ofcourse. Dig depth at 5'11", loading height 6'2".

I'm fairly sure the hoe is way too big for the machine. Nice excuse to get a bigger tractor

Also got a picture of some of the parts done so far. Alot of the parts for the swing joint are done too, and the stabilisers, just not welded together. Waiting for the hydraulics to turn up really....

at least 50 hp

at least 50 hp

That much work go in 1 garden tractor.

That much work go in 1 garden tractor. Expert on mud? Only when it comes to getting stuck in it

Expert on mud? Only when it comes to getting stuck in it