Island Runner

New member

Hi All,

First post here and hopefully I don't come off as ignorant on the RTVs. I have a few questions and will add some backstory so hopefully this isn't too long of a post.

I recently purchased brand new 2023 RTV X1140. I have about 800 acres of farmland, 40 acres of wooded swamp, 35 acres of wetlands, and about 12 acres of water in 5 ponds. The terrain is varying to say the least. I have steep dam walls around that separate the swamp land from the fields, I have grasslands, I have mucky swamp land that is always wet, I have wooded swamps, and I have woodlands. I hunt, fish, cut firewood, and maintain all of it and obviously need to access it in rain, snow, etc.

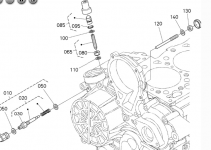

That said, and I have searched 50+ pages in this forum, but for a definitive answer what is the largest wheel and tire setup we can put on our RTV's? With the 2" lift and without the lift? I have attached a pic of RTV on 30 inch wheels for reference but have not been able to get any answers on how it performs with 30's. Any rubbing at full steering lock? Any rubbing when bottoming out suspension travel? I have seen 28" is the largest with a 2 inch lift and I have seen 30 inch is the largest with 2 inch lift. I come from building lifted big block V-twin golf carts and can see how the larger tires affect top speed and low end torque to a degree but that is with CVT transmissions. How does the HST transmissions handle bigger tires? I would think being hydro the effects of losing losing low end torque would be relatively small compared to CVT type drives but wondering if anyone has had a noticable decrease in low end torque/towing capacity from the larger 28" and up tires?

Along the same lines, how does the HST in these RTV's handle big mud tires? Can they turn the big lugged tires fast enough to get them cleaned out or are mud tires like the STI Outback Max and Interco UTV Bogger overkill for a RTV? I have been looking at those tires as they seem to be a good mix of mud tire and big lug tractor tire for maximum pulling force. Like I said, I need maximum ground clearance for the woods, mud tires for the swamp, and excellent traction for pulling. I will add that the machine rarely sees pavement. I do not plan on doing heavy deep mud bogging with it by any means but know inevitably I will caught in some deep muck from time to time. I do have about a mile of paved road I get on every now and then to get to one woods if there are crops in the field but I usually take the ditch anyway. I do not care about paved road performance or longevity. I honestly have not found a place to get it stuck with the factory ATV tires yet but this year has been exceptionally dry and the ponds are the lowest I have seen in 15+ years. I bought this machine to work and access all my land I can. I have other toys for speed and fun but they cannot work. Anyone have any insight or advice on any of this? Thanks!

First post here and hopefully I don't come off as ignorant on the RTVs. I have a few questions and will add some backstory so hopefully this isn't too long of a post.

I recently purchased brand new 2023 RTV X1140. I have about 800 acres of farmland, 40 acres of wooded swamp, 35 acres of wetlands, and about 12 acres of water in 5 ponds. The terrain is varying to say the least. I have steep dam walls around that separate the swamp land from the fields, I have grasslands, I have mucky swamp land that is always wet, I have wooded swamps, and I have woodlands. I hunt, fish, cut firewood, and maintain all of it and obviously need to access it in rain, snow, etc.

That said, and I have searched 50+ pages in this forum, but for a definitive answer what is the largest wheel and tire setup we can put on our RTV's? With the 2" lift and without the lift? I have attached a pic of RTV on 30 inch wheels for reference but have not been able to get any answers on how it performs with 30's. Any rubbing at full steering lock? Any rubbing when bottoming out suspension travel? I have seen 28" is the largest with a 2 inch lift and I have seen 30 inch is the largest with 2 inch lift. I come from building lifted big block V-twin golf carts and can see how the larger tires affect top speed and low end torque to a degree but that is with CVT transmissions. How does the HST transmissions handle bigger tires? I would think being hydro the effects of losing losing low end torque would be relatively small compared to CVT type drives but wondering if anyone has had a noticable decrease in low end torque/towing capacity from the larger 28" and up tires?

Along the same lines, how does the HST in these RTV's handle big mud tires? Can they turn the big lugged tires fast enough to get them cleaned out or are mud tires like the STI Outback Max and Interco UTV Bogger overkill for a RTV? I have been looking at those tires as they seem to be a good mix of mud tire and big lug tractor tire for maximum pulling force. Like I said, I need maximum ground clearance for the woods, mud tires for the swamp, and excellent traction for pulling. I will add that the machine rarely sees pavement. I do not plan on doing heavy deep mud bogging with it by any means but know inevitably I will caught in some deep muck from time to time. I do have about a mile of paved road I get on every now and then to get to one woods if there are crops in the field but I usually take the ditch anyway. I do not care about paved road performance or longevity. I honestly have not found a place to get it stuck with the factory ATV tires yet but this year has been exceptionally dry and the ponds are the lowest I have seen in 15+ years. I bought this machine to work and access all my land I can. I have other toys for speed and fun but they cannot work. Anyone have any insight or advice on any of this? Thanks!