Greetings All!

Got a 2007 RTV 900 with a small but bothersome leak in the transmission housing. I have narrowed it down to the piston housing at the rear right next to one of the transmission oil filters:

The gasket around this housing is likely worn as it drips from the bottom of the housing.

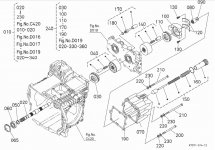

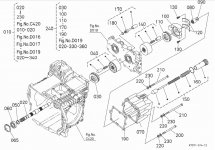

The service manual says to remove the piston case round plug (#1 in the pic above) and then proceed removing the 6-7 long bolts to release the housing and refit w/ a new gasket.

I just can't seem to get that plug loose - - it wont budge. Tried using a penetrating oil , impact driver, torch t heat, pound with hammer - - no luck. The assembly likely is under some type of pressure from the spring and piston assembly - part #150 in the IPL below. I need to replace gasket #190 in the IPL below.

Anyone replaced this gasket ? Any suggestions on how to move forward?

Appreciate all help and comments!!

Got a 2007 RTV 900 with a small but bothersome leak in the transmission housing. I have narrowed it down to the piston housing at the rear right next to one of the transmission oil filters:

The gasket around this housing is likely worn as it drips from the bottom of the housing.

The service manual says to remove the piston case round plug (#1 in the pic above) and then proceed removing the 6-7 long bolts to release the housing and refit w/ a new gasket.

I just can't seem to get that plug loose - - it wont budge. Tried using a penetrating oil , impact driver, torch t heat, pound with hammer - - no luck. The assembly likely is under some type of pressure from the spring and piston assembly - part #150 in the IPL below. I need to replace gasket #190 in the IPL below.

Anyone replaced this gasket ? Any suggestions on how to move forward?

Appreciate all help and comments!!