The famous saying goes something like this.....

"If I'd only known then what I know now".

This is the beginning of the story of the "Orange Buggy" as my wife calls the RTV900 we got at Ritchie Bros. auction back in November. We were looking for a side by side to use on our property and didn't want a new one so I found a bunch being sold off at auction and was confident I could pick out a good one from the 15 or so on the block that day. I checked them out and settled on a couple that looked OK. They were admittedly rough, but operational without too many overly obvious problems.

Auction day came and went and we were now the proud owners of a 2007 RTV900 with just over 2,000 hrs. We got it home that weekend and started to do a more thorough inspection than you could do at the auction site. What we found was a lot of evidence that this unit, and all of the others sold, must have worked on some sort of industrial construction sites that exposed it to some pretty harsh/corrosive/acidic/caustic exposures. It's not like parts were eaten away or dissolved, but all of the yellow electroplated parts all had a white crusty surface on the and all of the electroplated nuts and bolts looked the same.

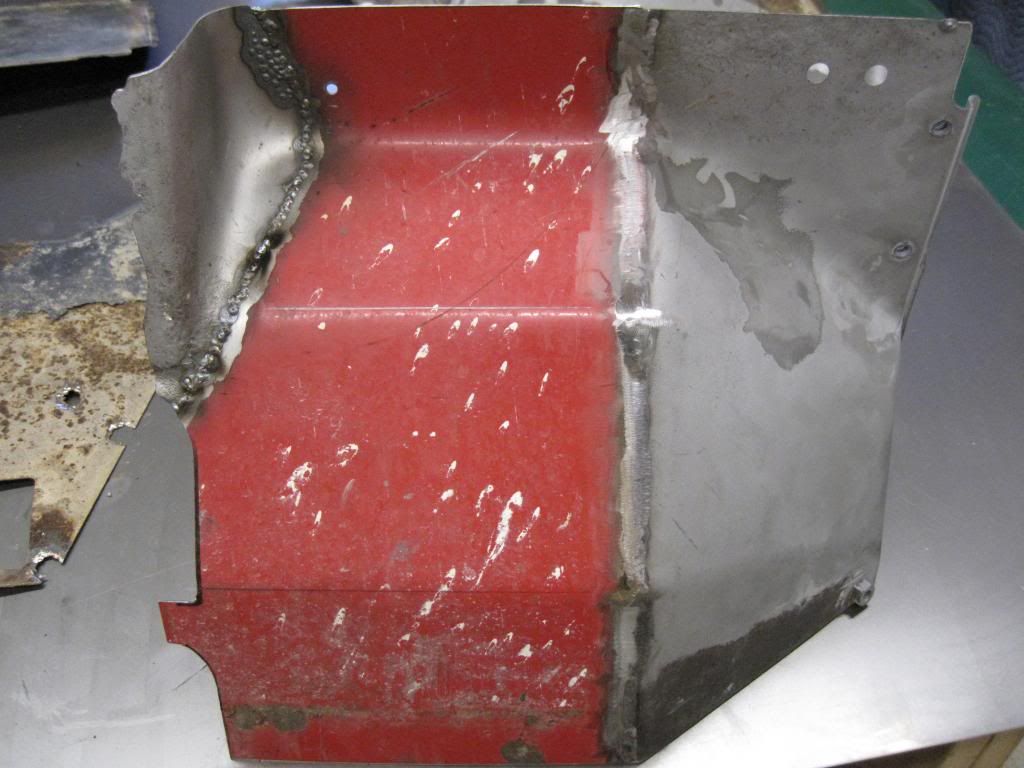

It was what was hiding under the floor mat that really told the story. Caked under the mat was a solid layer of moist sand that had really taken a toll on the floor boards.

Bottom of driver's side floorboard.

It was obvious that we were in for a much more involved "clean-up" than we originally thought. We were now looking at some rebuilding too.

So, out came the cut-off wheels and grinders and we jumped in with both hands and feet. All front sheet metal needed to be removed, fabricated and replaced. Kubota doesn't sell the parts, so we were on our own.

I also knew that there would be a whole lot of "while we're at it..." that was going to lead to a lot of extra work to get my wife's "Orange Buggy" back on the road.

More to come.....

-RFL

"If I'd only known then what I know now".

This is the beginning of the story of the "Orange Buggy" as my wife calls the RTV900 we got at Ritchie Bros. auction back in November. We were looking for a side by side to use on our property and didn't want a new one so I found a bunch being sold off at auction and was confident I could pick out a good one from the 15 or so on the block that day. I checked them out and settled on a couple that looked OK. They were admittedly rough, but operational without too many overly obvious problems.

Auction day came and went and we were now the proud owners of a 2007 RTV900 with just over 2,000 hrs. We got it home that weekend and started to do a more thorough inspection than you could do at the auction site. What we found was a lot of evidence that this unit, and all of the others sold, must have worked on some sort of industrial construction sites that exposed it to some pretty harsh/corrosive/acidic/caustic exposures. It's not like parts were eaten away or dissolved, but all of the yellow electroplated parts all had a white crusty surface on the and all of the electroplated nuts and bolts looked the same.

It was what was hiding under the floor mat that really told the story. Caked under the mat was a solid layer of moist sand that had really taken a toll on the floor boards.

Bottom of driver's side floorboard.

It was obvious that we were in for a much more involved "clean-up" than we originally thought. We were now looking at some rebuilding too.

So, out came the cut-off wheels and grinders and we jumped in with both hands and feet. All front sheet metal needed to be removed, fabricated and replaced. Kubota doesn't sell the parts, so we were on our own.

I also knew that there would be a whole lot of "while we're at it..." that was going to lead to a lot of extra work to get my wife's "Orange Buggy" back on the road.

More to come.....

-RFL