You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cat. 1 vs Cat 2

- Thread starter David69

- Start date

Jim_S

Super Moderator

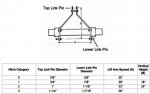

The arms are wider on cat 2 and the upper hitch point is higher. Your cat 1 might not spread far enough to fit. Sometimes you can turn the bottom pins around facing inward to fix this.

Very likely you will have to change the pins too. I think cat 1 is 7/8" dia and cat 2 is 1"

Jim

Very likely you will have to change the pins too. I think cat 1 is 7/8" dia and cat 2 is 1"

Jim

I don't know for sure, but if it fits the 3 point hitch and the PTO, I would try it. Bob

Thanks Bob,

I just recently found the measurements for Cat 1 and Cat 2. I do believe I can come up with a 3" spacer on each side of the tiller lift points and bolt it back together and it should work for the 26 inches. Luckily the lower link pins are 7/8' and not 1 1/8". The other problem I see is the vertical height distance which is 24 inches. It should be 18 inches.

Attachments

The arms are wider on cat 2 and the upper hitch point is higher. Your cat 1 might not spread far enough to fit. Sometimes you can turn the bottom pins around facing inward to fix this.

Very likely you will have to change the pins too. I think cat 1 is 7/8" dia and cat 2 is 1"

Jim

Jim what about the vertical height? It is 24 inches. Cat 1 is 18 inches.

Jim_S

Super Moderator

Jim what about the vertical height? It is 24 inches. Cat 1 is 18 inches.

Two pieces of strap iron with spacers in between to make them fill the space between the two tabs for the top link on the implement. The other ends should be wide enough for the ball of the top link to go between them.

I used to have a bush hog we fixed that way. It and the tractor were cat 2 but both the implement mfg and the tractor mfg were off.

I might have a pic somewhere I'll look.

Jim

Two pieces of strap iron with spacers in between to make them fill the space between the two tabs for the top link on the implement. The other ends should be wide enough for the ball of the top link to go between them.

I used to have a bush hog we fixed that way. It and the tractor were cat 2 but both the implement mfg and the tractor mfg were off.

I might have a pic somewhere I'll look.

Jim

A pic would be nice. Thanks so much

Two pieces of strap iron with spacers in between to make them fill the space between the two tabs for the top link on the implement. The other ends should be wide enough for the ball of the top link to go between them.

I used to have a bush hog we fixed that way. It and the tractor were cat 2 but both the implement mfg and the tractor mfg were off.

I might have a pic somewhere I'll look.

Jim

Another image

Attachments

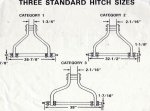

I love it. The first diagram shows 'standard' width for Cat 1 is 26", the second diagram declares the standard is 26 7/8".

This is significant if you use a Quick Hitch from Harbor Freight or TSC, and probably the Deere Imatch as well, because the width of a QH is not adjustable to match your 'standard' implement.

Standards are great, that's why there are so many of them!

This is significant if you use a Quick Hitch from Harbor Freight or TSC, and probably the Deere Imatch as well, because the width of a QH is not adjustable to match your 'standard' implement.

Standards are great, that's why there are so many of them!

The measurements are not that important. No worries about top link height. Lower arms on tractor should be parrallel with the top link when hitched. Your tractor should have at least two pin holes for the top link, choose the one that best makes them parrallel.

By the pictures it appears someone has already installed cat 1 pins. Should have no problem hooking up.

My Ford tractor has interchangeable lower links balls. I swap back and forth between cat 1 and 2 all the time.

By the pictures it appears someone has already installed cat 1 pins. Should have no problem hooking up.

My Ford tractor has interchangeable lower links balls. I swap back and forth between cat 1 and 2 all the time.

After studying your pics a bit more, it appears you can unbolt the lower pin brackets and move them to fit the need. Up/down and in/out. When you have your tractor in position to hook up you can then decide where to place the brackets to best fit your need.

Very rare to find an implement designed that way. Most times it requires modification of the implement to make things work. You are in luck!!!!

How wide is the tiller?? Next question might be having enough HP??? I run a 6' KK tiller with my 47HP Ford with no problems at all.

Very rare to find an implement designed that way. Most times it requires modification of the implement to make things work. You are in luck!!!!

How wide is the tiller?? Next question might be having enough HP??? I run a 6' KK tiller with my 47HP Ford with no problems at all.

IIRC, when my Dad encountered this, if your lower arms don't spread far enough apart, you just point your lower pins inward to decrease the spread.

In this picture, pull the pin pointing right, switch it so its pointing left (inward).

Yep. This implement is very versatile.

Rather than move the pins, I'd suggest unbolting the bracket and moving it. You don't want to mess with a tight pin anymore than you have to. It's the first thing that vibrates loose. These look like they are rusted pretty good. So you don't wanna mess with that.

Have you considered the weight of the implement. Sorry, I have no idea of the weight carrying capacities of Kubota tractor since I'm a John Deere tractor guy. The manufacture of this tiller is known for heavy duty an from the looks of the flat bar thicknesses in the pictures, the mfg didn't sacrifice on your machine.

Have you considered the weight of the implement. Sorry, I have no idea of the weight carrying capacities of Kubota tractor since I'm a John Deere tractor guy. The manufacture of this tiller is known for heavy duty an from the looks of the flat bar thicknesses in the pictures, the mfg didn't sacrifice on your machine.

On the L 4330 max lifting capacity is 3860. I should be ok.

Yeah you can handle it fine. I'm guessing the previous owner used a small tractor. That would explain why he has the pin brackets in their lowest setting so he could lift the tiller higher. A larger tractor would want them higher so it could be lowered farther.

Very versatile piece of equipment!!!!

You might want to check out the PTO slip clutch. They tend to rust solid from sitting.

Of course we'll need pics of you using it.

Very versatile piece of equipment!!!!

You might want to check out the PTO slip clutch. They tend to rust solid from sitting.

Of course we'll need pics of you using it.

Yeah you can handle it fine. I'm guessing the previous owner used a small tractor. That would explain why he has the pin brackets in their lowest setting so he could lift the tiller higher. A larger tractor would want them higher so it could be lowered farther.

Very versatile piece of equipment!!!!

You might want to check out the PTO slip clutch. They tend to rust solid from sitting.

Of course we'll need pics of you using it.

Thanks Richard...yes of course. I'll have to check it out further. It was attached to a MF 50 HP and it turned ok. I'll pressure wash it and get it into the shop (I think?.. running out of room). I believe it is a Series II Selectatilth. Can barely read the tag. Serial number 36725 . Tines are worn..Now to find a dealer that has parts? Thanks again for your valuable input

Attachments

I agree , I would sure check that clutch.Mine was stuck on a new tiller after I had let it get a blowing rain on it.I even had to take the plates loose because they were stuck good. cleaned and adjusted and all is fine. A "magic marker" and counting the number of turns on each bolt is important to get them back all the same "tension".

By the way, show ya'lls age.. magic marker .. that is what I call 'em.. collie

collie

By the way, show ya'lls age.. magic marker .. that is what I call 'em..